Need help!

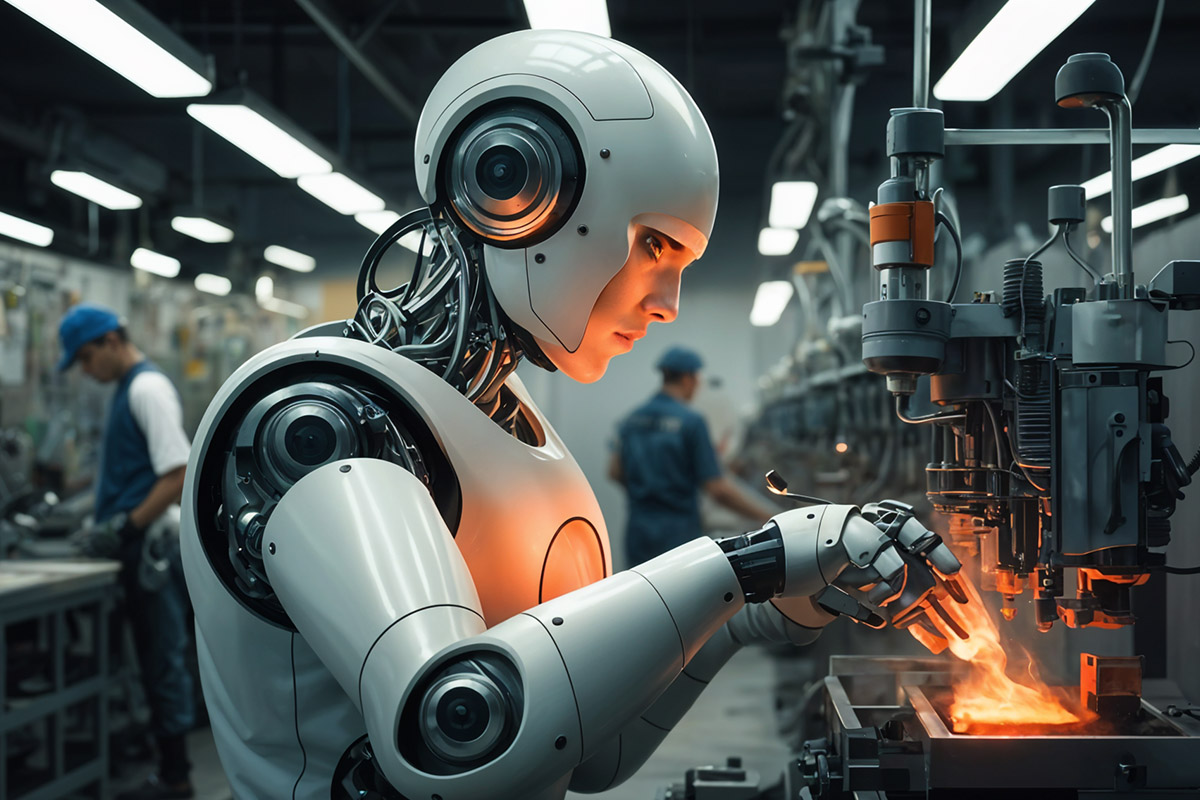

Strengthen your production line with Saan’s reliable auxiliary equipment.

Tablet coating is not just about aesthetics—it’s about functionality, protection, and performance. From taste masking and improved stability to controlled release profiles, the coating process determines the efficacy and patient acceptability of the final dosage form.

Saan Engineers offers R&D and commercial-scale tablet coaters designed for efficiency, scalability, and regulatory compliance. With advanced spray systems, energy-efficient air handling, and GMP-compliant design, our coaters deliver uniform, reproducible coatings batch after batch.

Uniform Film Application

Optimized spray gun design ensures precise atomization.

Scalable Design

R&D coaters to large-batch commercial systems.

Process Efficiency

Reduced coating times with superior drying efficiency.

Compliance Ready

21 CFR Part 11 compliant automation with batch reporting.

Flexible Operation

Supports aqueous and solvent-based formulations.

Easy Cleaning

WIP/CIP-enabled designs for reduced downtime.

R&D Tablet Coaters

- Compact systems designed for formulation development and trials.

- Coating capacity ranges from 500 g to 5 kg.

- Perfect for scale-up studies with geometry similar to commercial models.

- Variable pan speeds and air flow for controlled coating parameters.

Commercial Scale Tablet Coaters

- High-efficiency perforated pans for large-scale coating.

- Batch capacities from 15 kg to 500 kg.

- Automated spray guns with uniform distribution across tablets.

- Energy-efficient AHU with HEPA filters for controlled drying air.

- Optional containment systems for potent molecule processing.

Capacity

500 g – 500 kg batch sizes

Pan Type

Perforated coating pan with baffles

Spray System

Multiple spray guns with peristaltic pumps for uniform delivery

Air Handling

AHU with temperature and humidity control, HEPA/HEPA + H14 filters

Automation

PLC/SCADA integration with HMI touchscreen

Safety Features

Explosion-proof design for solvent-based coatings, nitrogen purging options

- Pharmaceutical Tablets –Film coating, enteric coating, controlled release profiles

- Nutraceuticals–Taste masking for herbal and dietary supplements

- Specialty Formulations – Stability enhancement, moisture protection, light shielding

- Ensures uniform coating thickness for consistent drug release.

- Reduces coating cycle time by up to 30% compared to conventional systems.

- Provides batch reproducibility across scales.

- Minimizes operator handling and cross-contamination risks.

- Fully compliant with global regulatory standards (USFDA, EMA, MHRA).

“Saan’s Tablet Coaters empower you to deliver tablets that are not only visually appealing but scientifically precise—ensuring every dose performs exactly as intended.”