Need help!

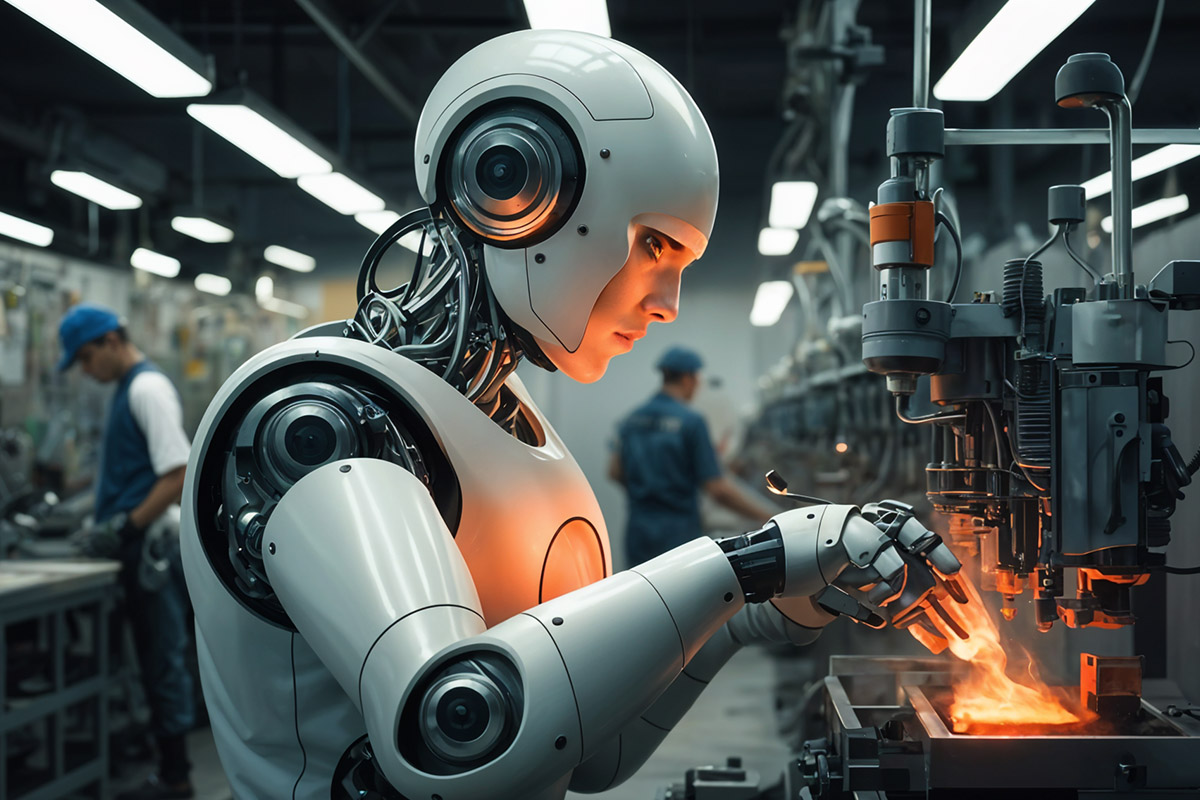

Strengthen your production line with Saan’s reliable auxiliary equipment.

Manual lifting and charging of materials introduces risks of spillage, contamination, and operator fatigue. Saan Engineers’ Lifting & Positioning Devices are designed to safely lift, align, and position containers, bins, and drums for direct charging into process equipment such as blenders, granulators, and tablet presses.

Built with GMP-compliant design and ergonomic operation, these devices enhance safety, reduce downtime, and streamline production.

Dust-Free Operation

Closed transfer prevents product loss.

Flexible Design

Mobile, fixed, and wall-mounted models available.

Easy Handling

Hydraulic or electric lifting with smooth positioning.

GMP Construction

SS 304/316L contact parts, polished finish.

Safety Systems

Interlocks, overload protection, and fail-safe brakes.

Load Capacity

50 – 1000 kg

Lifting Height

Up to 5 meters (customizable)

Actuation

Hydraulic or electric drive

Finish

Matt/mirror polish with dust-tight seals

- Charging powders and granules into blenders, mills, and tablet presses

- Safe transfer of APIs, excipients, and intermediates

- Suitable for multi-product facilities with frequent batch changeovers

- Eliminates heavy manual handling.

- Ensures operator safety and GMP compliance.

- Reduces batch contamination risk.

- Increases throughput with faster charging cycles.