Need help!

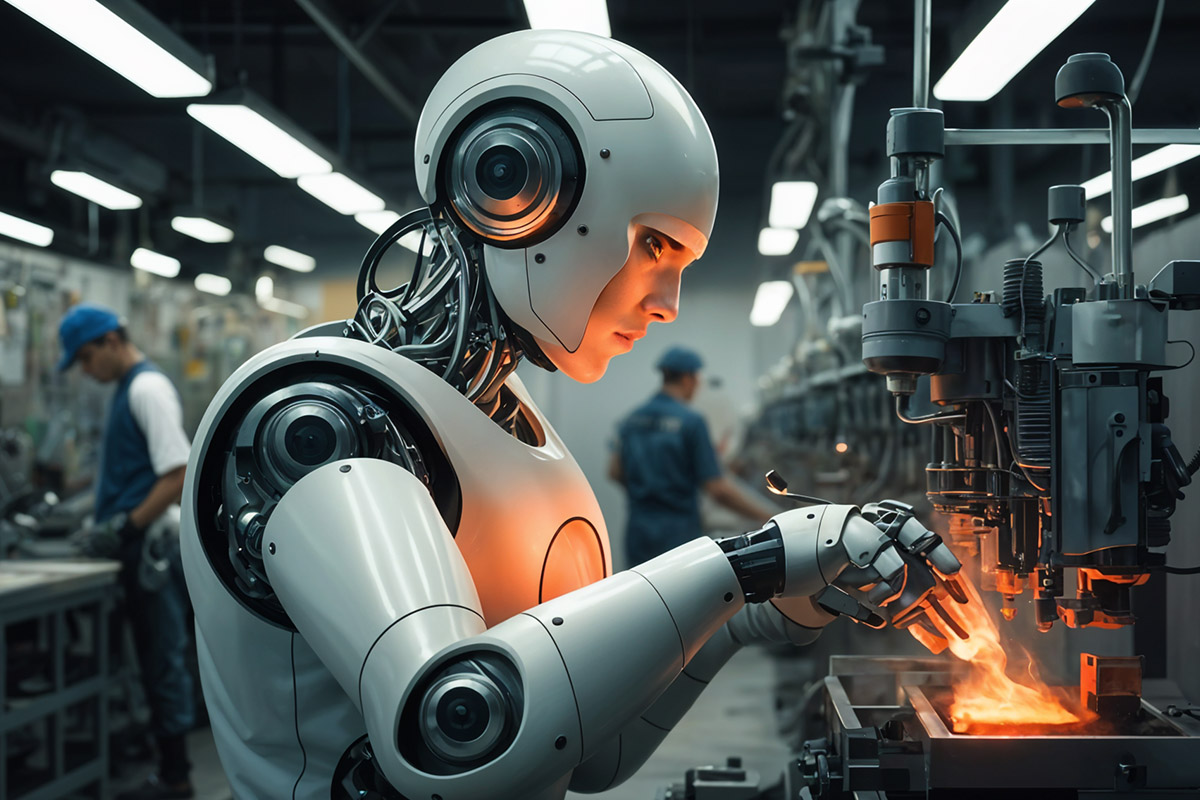

Strengthen your production line with Saan’s reliable auxiliary equipment.

Manual lifting and charging of materials introduces risks of spillage, contaminati

Drying APIs often involves sensitive, heat-labile materials that must be processed under controlled conditions. Saan Engineers’ Rotocone Vacuum Dryer (RCVD) provides efficient drying at low temperatures under vacuum, ensuring uniform heat transfer, solvent recovery, and batch reproducibility.

With its double-cone rotating design, the RCVD delivers gentle tumbling action, preventing degradation while achieving consistent drying results.on, and operator fatigue. Saan Engineers’ Lifting & Positioning Devices are designed to safely lift, align, and position containers, bins, and drums for direct charging into process equipment such as blenders, granulators, and tablet presses.

Built with GMP-compliant design and ergonomic operation, these devices enhance safety, reduce downtime, and streamline production.

Gentle Drying

Rotating cone ensures uniform drying without product degradation.

Vacuum Technology

Reduces drying temperature, ideal for heat-sensitive APIs.

Solvent Recovery

Integrated condenser for efficient solvent recovery.

High Safety Standards

Nitrogen purging and explosion-proof designs available.

cGMP Construction

SS 316/316L or Hastelloy for corrosive products.

Capacity

5 L to 5000 L

Drying Temperature

Up to 150°C (customizable)

Vacuum Level

< 1 mbar

Drive

Gear-driven cone rotation with variable speed

Compliance

USFDA, EMA, WHO GMP, ATEX (on request)

- Heat-sensitive APIs (antibiotics, hormones, oncology drugs)

- Solvent-rich intermediates

- Specialty chemicals requiring low-temp drying

- Prevents degradation of thermolabile products.

- Efficient drying with minimal energy consumption.

- Solvent recovery ensures sustainability and cost savings.

- Safe operation with explosion-proof options.