Need help!

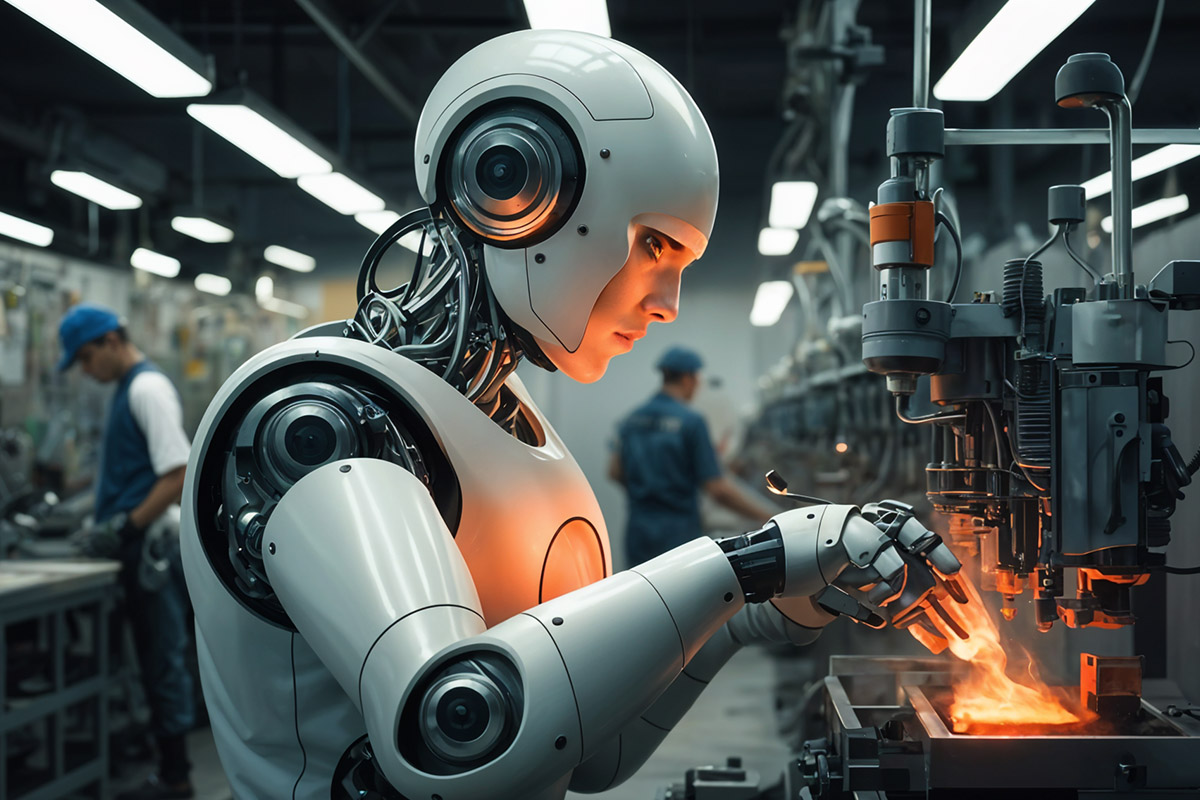

Strengthen your production line with Saan’s reliable auxiliary equipment.

Efficient material handling is critical to modern pharmaceutical and nutraceutical manufacturing. Poor handling can lead to cross-contamination, spillage, and safety hazards—all of which impact quality and compliance.

Saan Engineers offers a complete range of ergonomically designed, automated material handling systems that ensure safe transfer, dust-free operations, and productivity optimization across the shop floor. Our solutions are engineered for GMP compliance, operator safety, and seamless integration with upstream and downstream processes.

Operator Safety First

Dust-tight designs, enclosed systems, and ergonomic operation.

Seamless Integration

Compatible with granulators, blenders, dryers, and coaters.

Automated Operation

Reduces manual handling, improves cycle times.

Automated Operation

Reduces manual handling, improves cycle times.

Compliance-Driven

Built to meet stringent international standards (USFDA, EMA, MHRA).

- Designed to lift, hold, and position containers with precision.

- Ensures dust-free transfer of materials into granulators, blenders, or tablet presses.

- Available in fixed, mobile, and wall-mounted models.

- Dual-function system for lifting and controlled tilting of bins and drums.

- Enables direct transfer of material into process equipment.

- Reduces manual handling and improves ergonomics.

- Specialized lifter for bin inversion and discharge.

- Compact footprint, designed for high containment applications.

- Reduces manual handling and improves ergonomics.

- Pneumatic vacuum system for dust-free powder transfer.

- Reduces contamination risks while improving product recovery rates.

- Suitable for long-distance and high-volume conveying.

Technical Specifications

Load Capacity

50 – 2000 kg (depending on model)

Lifting Height

Up to 5 meters (customizable)

Construction Material

SS 304/SS 316L, mirror-polished contact parts

Construction Material

SS 304/SS 316L, mirror-polished contact parts

Safety Features

Overload protection, interlocks, dust-tight seals

Compliance

GMP and CE-certified systems, optional ATEX compliance

Pharmaceuticals

Safe handling of APIs, excipients, and granules.

Nutraceuticals

Transfer of herbal powders and dietary blends.

Food Industry

Hygienic transfer of powders and intermediates.

Specialty Chemicals

Handling sensitive or hazardous materials.

- Minimizes manual handling risks.

- Improves process ergonomics and operator safety.

- Ensures dust-free transfers and higher containment.

- Reduces batch turnaround times with faster material movement.

- Enhances compliance with validated cleaning and GMP design.

“Saan’s Material Handling Systems are engineered to keep your production floor safer, cleaner, and more efficient—delivering reliability from raw material charging to final product handling.”