Need help!

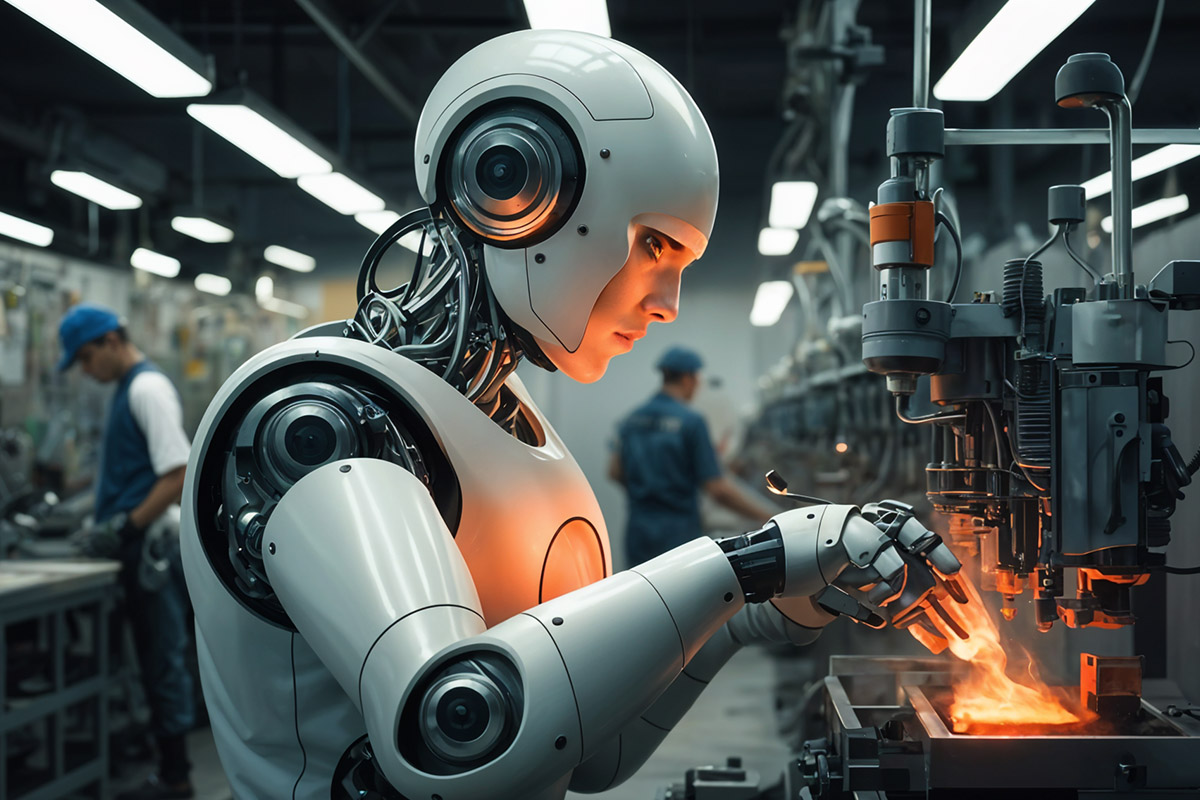

Strengthen your production line with Saan’s reliable auxiliary equipment.

Powder transfer is one of the most critical and contamination-prone stages in pharma manufacturing. Saan Engineers’ Vacuum Transfer Systems ensure enclosed, dust-free conveying of powders and granules over short or long distances, maintaining both operator safety and product integrity.

These systems reduce manual handling, improve process efficiency, and ensure compliance with GMP and containment guidelines.

Dust-Free Operation

Enclosed pneumatic conveying.

High Throughput

Handles large batch transfers with ease.

Long-Distance Transfer

Capable of conveying powders across multiple floors.

GMP Design

SS 316/316L contact parts, hygienic build.

Automation Ready

PLC integration with programmable recipes.

Capacity

Up to 5 tons/hr

Conveying Distance

Up to 30 meters

Vacuum Source

Compressed air / vacuum pump

Filters

HEPA/anti-static filters for

containment

Compliance

ATEX-ready for explosive powders

- Safe transfer of APIs, excipients, and intermediates

- Nutraceutical powders and herbal extracts

- Hygienic transfer in food and chemical industries

- Eliminates dust and contamination risks.

- Reduces manual handling and labor costs.

- Improves efficiency of downstream processing.

- Fully compliant with global regulatory requirements.